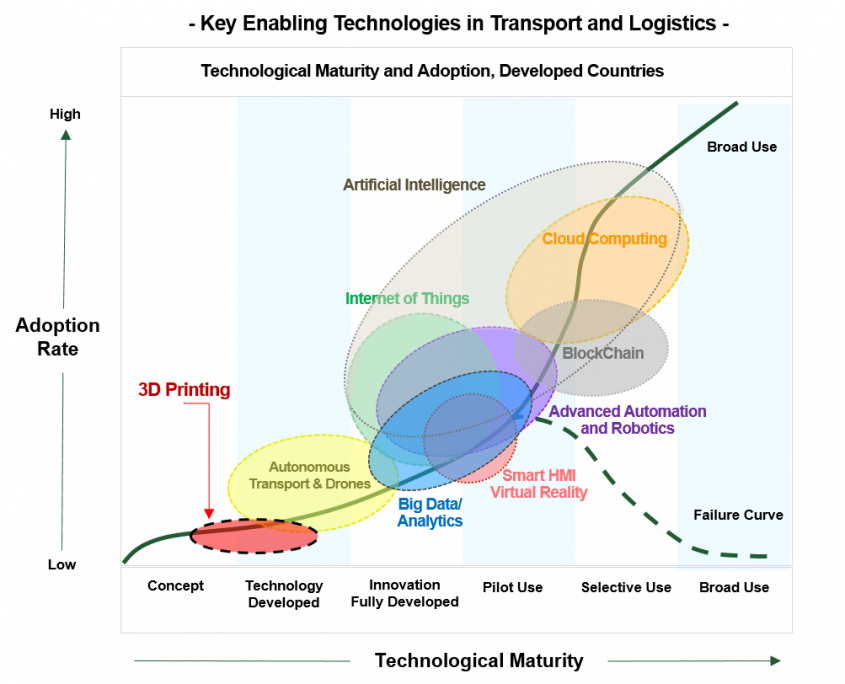

Industrial 3D Printing is significantly different from the rest of KETTLs being presented as it does not rely on the integration and mutual leverage of pre-existing and fast evolving technologies. Along with Autonomous Vehicles is the only one truly disruptive, meaning that once a certain degree of technological maturity and cost efficiency is achieved 3D Printing has the potential to alter accepted, well established modes of design and development, production, transport, distribution and consumption. 3D Printing is also the less mature of all technologies presented, with already started but still limited industrial level applications, however done its innovative, disruptive and value creation possibilities is a technology to be watched closely.

CETMO Analysis, adapted from McKinsey & Company (1)

3D PRINTING DEFINITION

3D Printing is the process of building products additively, layer by layer, instead of by traditional manufacturing methods like press-shaping or molding. 3D printing uses precise geometrical representations like CAD and digital 3D models, advanced modeling technology, and automated addition of liquid molecules or powder grains mainly of plastic and metal, fused together through an increasing variety of layering techniques.

3D printing began in the 1980s with a polymer-based technology called rapid prototyping. In this process, the goal was to build a draft of a particular part before investing in creating an expensive mold for a production line. Today’s 3D printers provide more accuracy and precision than rapid prototyping because the design of the object is created separately in 3D software. High-end 3D printers actually allow multiple materials to be fused together in one print.

ADDITIVE MANUFACTURING DEFINITION

Additive Manufacturing (A.M.) is a broader concept. It includes first the processes of 3D model design and data transfer that requires constant innovations in computer-aided design and computational power. Additive manufacturing also includes at its core 3D Printing technology that still requires further new materials able to being used. Thirdly AM includes post printing processes of material removal and object finishing and printer resetting, stage that still can be greatly improved with additional automation and certification standards.

ADDITIVE MANUFACTURING EVOLUTION AND ADVANTAGES

AM present expansion is expected to continue due to the constant increase of materials that can be handled. Already a wide range of new plastics has been developed, along with techniques and printers able to use ceramics, glass, cement and even advanced materials like graphene. 3D Printing can also manage food, living cells and human tissue.

Additive Manufacturing has already started to be economically profitable for large industrial production, because Economies of Scale do not apply like in mass production. Present manufacturing relies on equipment and processes that generate Economies of Scale so the large the production, the cheaper the unitary cost of an item.

Mass production efficiency has the downside of no or limited customization, and the fact that items with a below-the-threshold demand that does not justify mass production and either is produced in small batches at higher costs or simply not produced industrially. This generates an unsatisfied demand along with a customer behavior prone to disposal rather than maintenance.

Additionally, once AM will reach a sufficient level of efficiency, it will progressively address the costs and limitations of transport and storage. Present industrial manufacturing produces in centralized locations, large volumes that require costs of storage and warehousing, inventory and transport. Indeed, AM can be done in small batches or even single units, near where final user is located and even on user’s premises.

AM is already producing rapid prototyping and production of part replacements, and products difficult or expensive to get through mass production. Some examples of present uses are repair of burning heads in gas turbines with 44 to 4 weeks’ time reduction, fuel nozzles 25% lighter and five times more durable, metal brackets for aerospace industry with a 50% reduction in weight industrial filters, hearing aids, healthcare tools and prosthetics.

Given these factors, it is clear that AM could have broad business implications and drive substantial cost savings in areas like product research, development, testing, and production, packaging, storage, and change completely shipping, transport and the overall value-chain. AM offers Passenger Transport with some value creation opportunities as described in the KETTL Effects section of this website. Regarding Freight Transport and Logistics, AM represents less an opportunity and more of a potential threat as the whole concept of product transportation and distribution could be completely altered.

ADDITIVE MANUFACTURING EFFECTS ON DISPARITY

The disruptive potential of AM also generates important opportunities for developing countries. AM allows for a single machine to produce a variety of products, which could lead to multi-purpose factories, broadening manufacturing to areas with no o limited pre-existing industrial base. AM offers the possibility to manufacture customized products with just a fraction of the investment required for a traditional factory, this has already been applied in India for the construction of automobile parts.

Additionally, 3D design behind AM, and the printer applications, can be transferred though internet, thus removing technological barriers and facilitating innovation, creativity, de-centralization and democratization of production while making design and modelling the most value-added activities.

AM has proven potential for more sustainable and resource efficient manufacturing due to be able to produced lighter, more durable products with less material used per unit and also with far less material wasted, to the point that it is estimated that by 2050 AM could reduce the consumption of energy globally by 27%(2).

Additive Manufacturing is still a not mature technology, it is advancing quickly with already industrial and commercial uses. What makes this KETTL worth to take under scrutiny is its potential enormous effects in production, transport, consumption and the ability to reset whole economies and generate new ways of creating economic and social growth in all kind of countries.

References:

- McKinsey & Company. Ashutosh, Hastings, Murnane, Neuhaus, Automation in Logistics: Big Opportunity, Bigger Uncertainty, 2019. link

- The Economist Intelligence Unit, 2018.

Industrial 3D Printing added to advances in new materials can represent a true new form of industrial production, significantly reducing the need for freight transportation thus changing shipping patterns and business relationships between suppliers and customers. Also may completely change distribution and retail sale for certain types of products.

Additionally, these new and more decentralized forms of production will likely make companies’ location less relevant, and will provide independence from suppliers. 3D Printing with its immediacy, higher responsiveness and customization possibilities may also generate higher customer satisfaction as well as new customer needs and new services to satisfy them. Some effects include:

Freight Transport

Partially Meshed Production and Logistics: for many product categories, some parts of the “just-in-time” production cycle can be completed in distribution centers or in stages after the origin (factory), even near or at the customer facility thanks to the ability to generate parts, spare parts, etc. at any stage of the cycle (including transport). Transport will start without having to wait for large batches, reducing the total delivery time.

Integration of Production during Maritime Transport: in the case of maritime transport the production itself of certain products can occur in the course of the voyage itself (production cycle products that need a lot of speed, or that help reduce production time to reduce the total time of the full product cycle). The design of the product and its entire production cycle will be modified so that transport is a related part in production.

New Types of Commercial Agreements and after-sales services. The possibility of industrial-scale 3D production near or at the same facilities of the customer will open the door to separate agreements for full and partial production, raw material supply, technical support and patents.

Reduction of Urgent Shipments generated by lack of spare parts, or very urgent parts, due to in-house or near –in-house quick customized production.

Passenger Transport

Change and New Roles: Operators will be able to manufacture itself many of the required equipment on premises and near-premises. Also manufactures may continue manufacturing as delegation on the operator’s premises. Exists also the possibility of new companies specialized in the quality and know-how of 3D Printing being outsourced by the operators, while original supplier will become the providers of patents and original know-how.

Increased Operator Autonomy: 3D Printing will reduce the commercial dependence to part suppliers as operating companies will be able to manufacture the parts themselves or have it outsourced in their own premises.

Accelerated Production Time allowing the manufacture of spare parts on site and instantly, without depending on suppliers and improving the speed of response, should greatly facilitate the maintenance of facilities and vehicles.

Reduction of Urgent Shipments due to in-house or very near quick customized production of spare parts or very urgent parts.

Sources: CETMO and “Impacte de les KETs en la digitalització dels diferents àmbits del transport”, CENIT-CINESI – December 2020

With the support of:

Contact

Av. de Josep Tarradellas, 40, entresol

08029 Barcelona

Tel: 00 34 93 430 52 35