Automation and Robotics have been part of manufacturing and logistics for decades delivering efficient operations, better quality products and generating proved value to the organizations that adopted them. Their design has been evolving continuously broadening the range of types and capabilities that can develop. As the rest of KETTLs,

Automation and Robotics have advanced dramatically in the last decade leveraging and integrating other KETTLs like IoT and IA. This integration has also resulted on further innovative technologies like Autonomous Vehicles and Drones.

AUTOMATION, DEFINITION AND TYPE

We will start by clarifying some concepts. Automation is the process of using physical machines and computer software to carry out tasks which would otherwise be done by human workers. In other words, is the replacement of repetitive tasks and transactional processes conducted originally by humans by automatic mechanisms managed by IT Systems. This replacement usually results in an improvement in efficiency, and reallocation of human resources workload ideally towards more value-added tasks. There are many types of automation, ranging from the fully mechanical to the fully digital, from very simple to the enormously complex, with and without Robotics. There are three families of Automation depending on the range of tasks they can do without reprogramming: Fixed, Programmable and Flexible Automation.

Fixed Automation

It involves the deployment of a specific device or machine to automate some relatively simple operational sequence of tasks and assembly operations. At industrial level often involves repetitive movement and physical manipulation. This improves the rate of production at lower cost. Its two limitations are first that Fixed Automation allows the repetition of only the same exact tasks, exactly in the same way and only producing identical outputs. Secondly the same machine cannot be used for variations of even very similar tasks.

Programmable Automation

Programmable Automation allows for reprogramming of the machine by engineers or users, so the machine can conduct variations of the same or very similar task, for example adjusting for the next batch of production. The advantage is greater flexibility so the machine is able to be used for similar other tasks without the cost involved in purchasing additional machines.

Flexible Automation

It’s use provides automated machines with further flexibility and the capacity to rapidly change among already programmed sequences, like production design variations. Flexible Automation supports production of a wide range of outputs with negligible downtime and high production rate. Because there is no need for reprogramming, machines can easily switch between sets of programmed tasks allowing Batch-Production and also On-Demand Production. For users it allows them to expand the range of functionality of a device by a simple change of pre-set commands.

ROBOTICS, DEFINITION AND THE PRESENT INDUSTRIAL AUTOMATION

Definition of Robotics

Robotics is the field of knowledge that integrates computer science and engineering to design and build Robots. Also can be defined as the process of designing, creating and using robots to perform a certain task. Robots, based on programmable Automation, are machines able to conduct actions autonomously, or quasi-autonomously in a way beyond mere automation as: a) Robots are autonomous within the limitation of the set of tasks they are designed for, and b) more importantly, Robots interact with the physical world via sensors and actuators and are able to adjust the execution of their task.

Presently Common Industrial Automation

It is defined as the automation of physical processes using physical robots to automate tasks within an industrial process, like in the case of car factory or even a fully autonomous factory. Industrial automation is all about controlling physical processes.

A further step technology, Robotic Process Automation, allows software robots to use an application’s user interface (UI) to mimic human actions without modifying systems or requiring human intervention. This approach is effective for automating rule-based tasks like that use structured digital data, like sorting items for example.

THE NEW WAVE OF AI POWERED AUTOMATION AND ROBOTICS

Intelligent Process Automation results from the convergence and integration of Automation, Robotics and Artificial Intelligence. It is a technology that uses AI to automate business processes that require sequence, physical action and judgment. Intelligent Process Automation provides a cost efficient sophisticated and flexible automation for an ever expanding range of task, which along falling costs explains the continuous expansion of robotics worldwide.

AI POWERED AUTOMATION AND ROBOTICS, ADOPTION AND EFFECTS

The integration of Automation. Robots and AI has consolidated and expanded production, adoption and use of Robots due to a combination of factors.

Technological Advancements and Cost Reduction

On one side, accelerated advancements in sensors and applications, provide new Robots with cost-efficient added capabilities. On the other side The cost of Robot is falling, indeed the average robot price has halved (1) over the past 30 years. Additionally robot manufactures are responding to increasing demand from emerging countries by increasing production volumes achieving larger economies of scale and transferring the cost reductions into further price reductions.

Additionally the AI behind advanced robotics continues advancing as explained in its dedicated section, and further integrated with a steady advancement in integration methods.

As the cost and complexity of automating tasks with robot’s decreases, we can expect an increase in its adoption and deployment by companies, operators and authorities in transport and logistics.

General Global Adoption

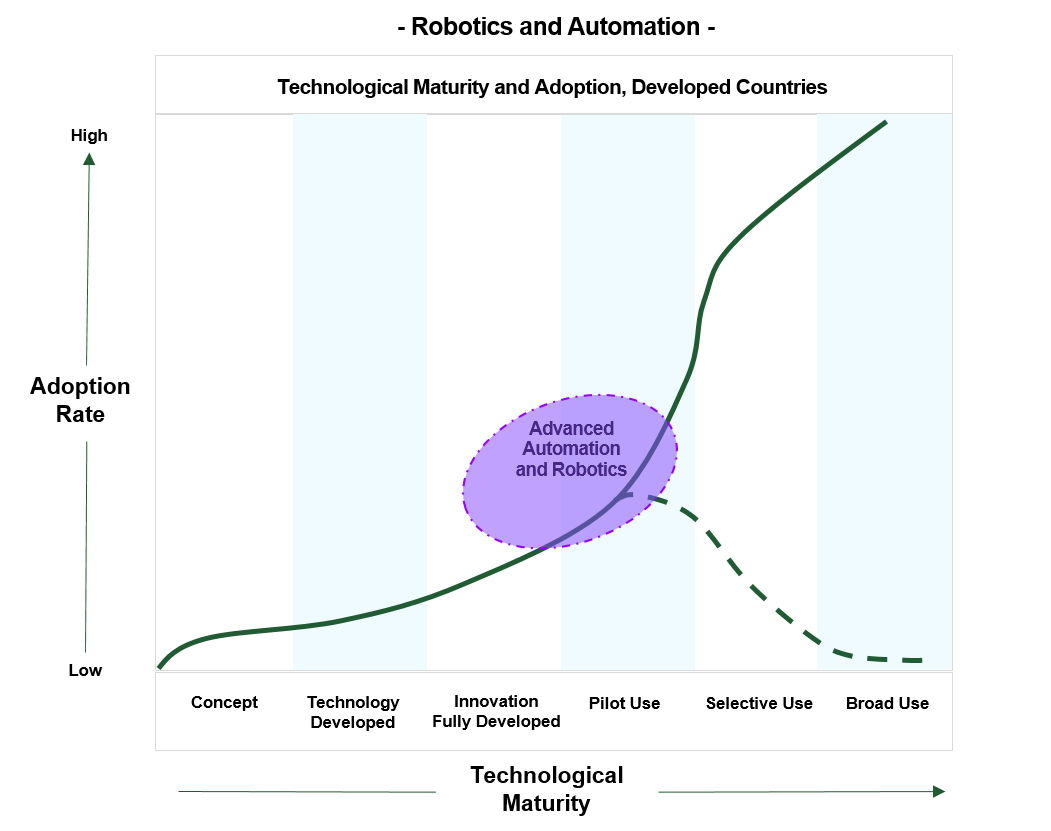

CETMO Analysis, adapted from McKinsey & Company (2)

These elements support a strong case for a general global adoption of Advanced Automation and Robotics. Additionally, the time required for the technological adoption to become fully general and mature is considered to be less than 5 years (2). Already companies and operators that were early adopters and fast followers are reaping the benefits. Therefore, those not already considering or at least exploring its use may be positioning themselves in a more difficult competitive position, with more difficulties to provide a competitive service and the possibility of waiving an opportunity to increase economic and social value in the near future.

References:

This technology has bee part of manufacturing for decades, now the falling prices, increasing demand from developing countries and mid-size operators plus the integration of AI through Cloud Computing further expand its applications and uses.

Freight Transport

Increased Demand Absorption Capacity and Value Chain Fluidity: Robotics and Automation ensures that physical and administrative repetitive tasks are executed more efficiently and autonomously, also reduces interruptions and staff interventions. The net result is an increase in demand absorption capacity a further value chain fluidity.

New Staff Skills Required: one of the effects of Automation is the realignment of labor dedicated to transacional operations into personnel dedicated to the supervision, maintenance, development and design of the product.

Passenger Transport

Process Efficiency Gains: Automation, improves efficiency in the execution of processes related to planning (e.g. service design), operations, business aspects, and support and demand issues. This frees staff from mechanical work and gives them more capacity to respond to other types of tasks. It also means improving efficiency (reducing costs and increasing passengers).

Sources: CETMO and “Impacte de les KETs en la digitalització dels diferents àmbits del transport”, CENIT-CINESI – December 2020

With the support of:

Contact

Av. de Josep Tarradellas, 40, entresol

08029 Barcelona

Tel: 00 34 93 430 52 35