Internet of Things is a form of distributed computing based on networks of devices embedded with sensors and interconnected by internet. Each device contains sensors, actuators and software to measure physical parameters plus internet, connection, with the objective of connecting with other device and exchange data to either mutually help each device to better accomplish its individual task by receiving more physical information or by together accomplish a combined task.

INTERNET OF THINGS (I.o.T) DEFINITION

The term first became popular in 1999 in an internal presentation by Kevin Ashton for M.I.T. and Procter & Gamble (1). Its initial use was for RFID tags (Radio Frequency Identification) and immediately was applied to consumer product uses, in home appliances like smart TVs, in wearable technology, and above all in smart home and domestics, interconnecting appliances like lighting fixtures, thermostats, home security systems and cameras.

IoT is one of the rare cases when its surrounding hype is indeed understating its real full potential. IoT has already enormously helped in the previous Digital Revolution by facilitating the digitalization of the physical world. The innovation capacity of IoT has increased and currently is being integrated with other technologies like Robotics, Big Data Analytics and AI allows for an enormous range of applications to the point of being considered one of the pillars of the 4th Industrial revolution.

ENABLERS OF THE PRESENT INDUSTRIAL INTERNET OF THINGS (I.I.o.T.)

Industrial Internet of Things (IIoT) refers to the use of IoT initially in industrial production and by extension to any sector. IIoT focuses on the networking of machines to achieve seamless process chains by leveraging and integrating AI, BigData Analytics and Automation and Robotics technologies including technical advancements in wireless sensors, radio frequency identifications tags (RFID) GPs, and internet protocols and achieving important increase of companies and operator’s effectiveness.

TECHNOLOGICAL COMPONENTS

Low Cost Sensors and Actuators

Low cost, miniaturized sensors, actuators and intelligent devices collect physical and chemical parameters, such as temperature, humidity, amount of light, gases, and data related to predictive maintenance and energy efficiency and they are of general application in monitoring of machines, and installations. An actuator is a device, that in order to automate a process, is capable of transforming energy into an action, like relays to cut of electrical current, indicator lights and solenoid valves. The data collected by sensors and actuators is then sent seamlessly to Cloud servers.

Cloud computing Provides BigData Processing

CC provides it without the requirement of fixed capital, and then the resulting information is used as the base for automated processes. Major cloud providers such as Microsoft, Amazon Web Services and Google and a myriad of specialized players now provide IoT platforms, the computing power and the analytics that facilitate the development and administration of IIoT applications.

IIoT Platforms and Applications

The building blocks of an IIoT system are specialized tiered applications generally located and managed by powerful cloud-based IoT Platforms that collect data from de devices’ myriad of sensors and actuators, and after analysis makes the information available to users, operators and also sends instructions back to the original and new devices. Just to provide an illustration of the extend of present services provided, there are three tiers of applications: The first tier are Enterprise Operation and Integration applications that monitor the environment, tasks, vehicles, engines engine status etc and integrates the data at enterprise level.

The second layer of applications provide historical analytics based on AI and connection to people, and downstream the information to generate alarms, alerts, rules to conduct processes and changes in those rules

Additionally, there is a third layer of applications to apply the analyzed data to improve the devices and sensors drivers and their management.

IIoT ADOPTION AND EFFECTS

The combination of sensors powerful on-demand Cloud Computing and IoT Platforms allow devices to provide optimize functions in, among other areas, smart maintenance, operations management, fleet monitoring, route monitoring, remote area surveillance, and smart warehouse and inventory management. To illustrate the IoT’s economic impact, the improvements in inventory, logistics and overall supply chain is estimated to reach a global annual savings of €460 to €700 billion by 2025. (2)

CETMO Analysis, adapted from McKinsey & Company (3)

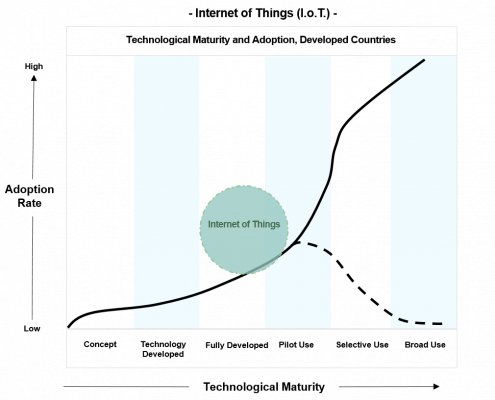

As discussed in the AI and Automation and Robotics sections, IoT also presents a broad range of uses and acceptable adoption that is expanding rapidly with key players in manufacturing and logistics already reaping its benefits. DLH estimates the general adoption and deployment of this technology with a high economic impact will happen within 3-5 years, faster than for example Robotics and Automation and AI (4). Additionally, IoT component manufacturers and platform and service providers continue to consolidate and expand its offerings. Just regarding IoT Platforms, Microsoft, IBM, Oracle, SAP and Hitachi offer such reliable services.

IIoT EFFECTS ON CORPORATE AND COUNTRY DISPARITY

IIoT has been identified from its inception as a KETTL that generates large benefits not only to logistics but also and particularly to all passenger and freight transport sectors. Indeed, the quick advances, falling costs, scalable nature, and sufficient adoption already taken place facilitates some kind of adoption with limited risks even to small operators and is already generating a small boon for smart modest adopters.

IIoT has a clear application in developing countries to bypass present limitations in infrastructure, for example in fleet management and location in transportation, city management, sustainable energy in isolated areas with low cost use of solar energy, and innovatively pay as you go transaction models using IoT enabled devices.

References:

- RFID Journal, Volume 22, Ashton,Kevin, The Internet of Things, 2009

- Mackinsey & Company, The Internet of Things: Mapping the Value Beyond Hype, 2015 link

- McKinsey & Company. Ashutosh, Hastings, Murnane, Neuhaus, Automation in Logistics: Big Opportunity, Bigger Uncertainty, 2019. link

- DHL, Logistics Trend Radar, 5th Edition, 2020. link

The distributed computing allowed by IoT, with the collection of the myriad of data provided by the sensors and actuators embedded in devices, and their analysis in the Cloud by 3rd part application providers, and the instructions sent back to the devices to correct and act allows an impressive level of automated efficiency and a broad range of effects, some are:

Freight Transport

Planning quality is significantly increased by having multiple additional inputs. Planning is more precise, detailed and better adjusted to reality as a result the delta between Planning and operation is reduced.

Better control of port operations such as stowage and cargo control. Fuel consumption control and fuel emission reduction. Improving risk detection and prevention.

Goods’ Location in real time and with complementary information (temperature, humidity, security control, replacement of containers, …) that allows a more effective control of the goods that need a particular treatment.

Uninterrupted Traceability throughout the logistics process, and integration with different agents, including the customer himself. Traceability of loads and real-time service performance indicators are automatically processed, resulting in a more accurate picture of the company. Improves understanding of the business, and the

Added Transparency and updating of the organization’s information towards customers, due to autonomous and automatic collection and delivery of information.

Passenger Transport

Universal Access: immediate and complete access to planning data.

Near Total Operation Control: including for example infrastructure’s state, location of the fleet, consumption including integration of information from different agents.

Multi-Agent Traceability of commercial procedures, in real time, with indicators accessible by the different agents involved in the processes.

Procedures and Transaction Traceability such as requests, orders, suggestions, complaints, claims, improving the relationship between all participants (suppliers, operators, users).

Sources: CETMO and “Impacte de les KETs en la digitalització dels diferents àmbits del transport”, CENIT-CINESI – December 2020

With the support of:

Contact

Av. de Josep Tarradellas, 40, entresol

08029 Barcelona

Tel: 00 34 93 430 52 35