Bjelovar, Croatia - 2016

Domain of application: Local

Status: Existing

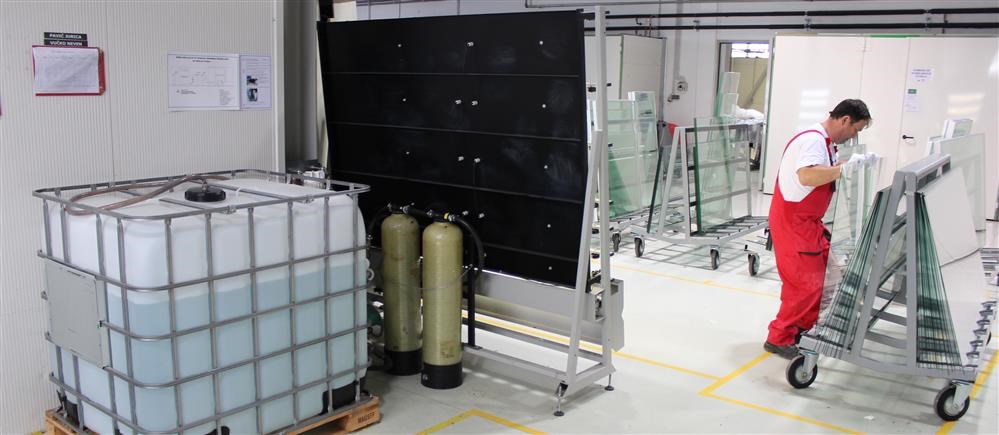

Metalind in Croatia increased product quality and reduced water consumption thanks to extra filtration that makes it possible to use the same water in up to 80 production cycles.

Metalind used ordinary tap water to rinse fire-resistant glass during the production process. An open system was used, with clean water taken from the municipal water mains network and waste water released into the sewerage system. Moreover, the water’s chemical composition was a problem, as it contained unacceptably high levels of iron and chloride content. This entailed an imminent risk of customer complaints due to optical defects in the glass.The solution was to install a water recycling system. Extra clean water is now purchased in IBC containers, added to the system and used during production. The main change is that the plant now has a closed water system. When the production process is finished, the water is filtered and then reused. The same water can be used up to 80 times without a deterioration in quality.

Water consumption has been reduced appreciably, helping Metalind to meet one of its the sustainability targets for 2015. However, the main advantage is that product quality is much improved. Another important advantage is that customer complaints have fallen considerably since the new glass cleaning method was introduced. Moreover, the production plant is no longer dependent on the municipal water supply system and is not affected in case of a water shortage.