Renaul team - 2007

Domain of application: Globally

Status: Existing

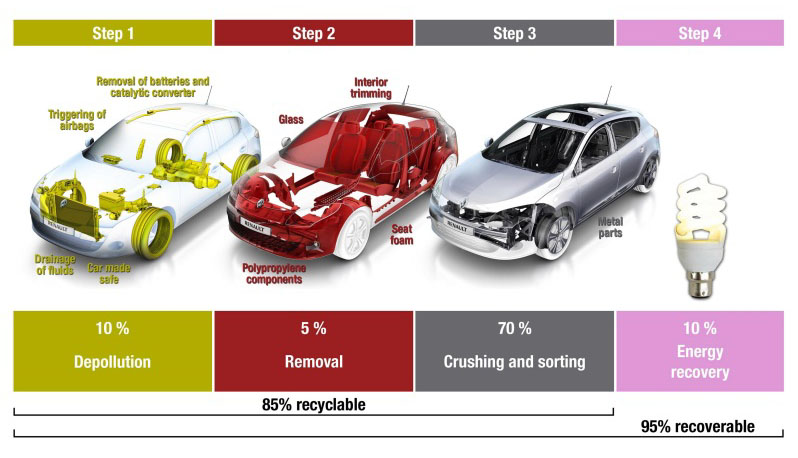

Renault is backing the circular economy and is working on recycling options in order to protect the planet by avoiding using up resources. For Renault, the circular economy begins with eco-design. Vehicles are created to be 85% recyclable and 95% recoverable at end of life, and recycled materials are used as much as possible in manufacturing.

The Renault company has embraced the idea that nothing should go to waste in a productive system. All the materials used in their cars should ideally be potentially reused, recycled to enter the system again or composed, without taking new resources. At the same time, energy consumption must be reduced to the maximum in the production process.

Now a Renault Space made with over 90% recycled materials is available in the market. The average of any other model is 30%, and by the end of 2016 should be 33%. On top of that, Renault is investing in its subsidiary Indra to dismantle “end of life vehicles”, using them as a resource for spare parts, and further recycling of components and materials.

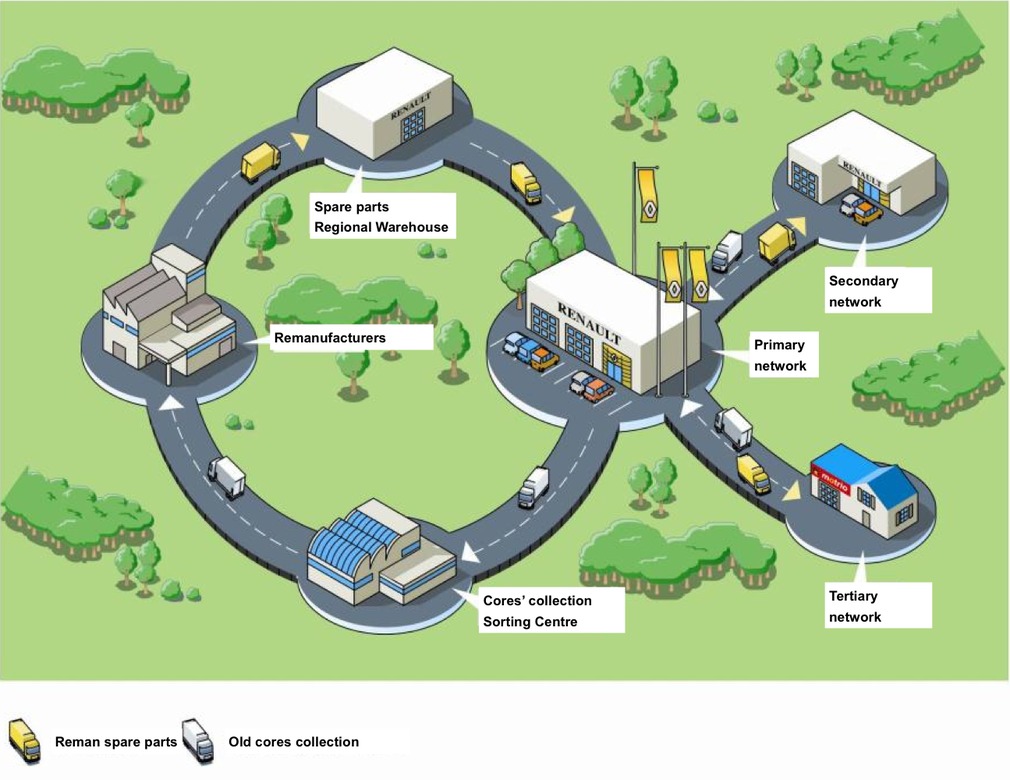

According to Laurent Claude, Business Developer Renault Environnement, the parts destined for re-manufacturing, called ’scraps’, which can be used in 90% of cars in our range, are dropped-off to vehicles in-use /owned. By using reverse logistics of distribution of spare parts, the scraps are collected by the commercial network.

Renault affirms that the savings from the production of a remanufactured part compared to a new part are as follows:

- 80% less energy

- 80% less water

- 92% less chemical products

- 70% less waster production

- 43% of the carcasses are re-usable

- 48% are recycled in the company's foundries to produce new parts

- the remaining 9% is valorised in treatment centres meaning the entire process is waste-free