Circular Glasgow: growing into a greener economy

- Glasgow Chamber of Commerce

- Zero Waste Scotland

- Glasgow City Council

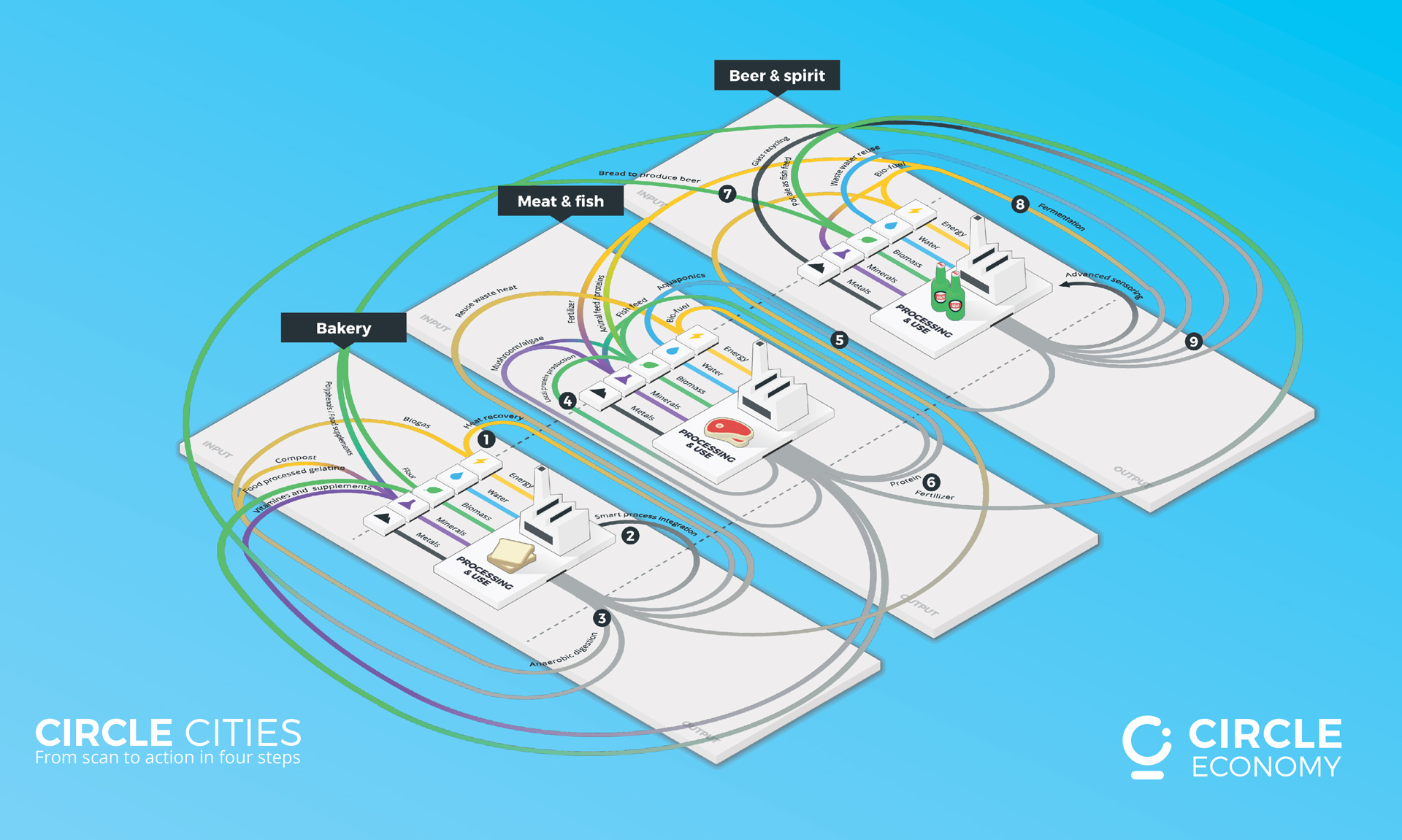

- Heat recovery. In a bakery, nearly 20% of the toal energy consumption is from the boilers to heat process water and produce steam. This water and steam is used for: area heating, whasing and proofing the bread before it is baked. Heat from bakery ovens can be recovered and redirected to the boilers by using heat exchangers saving 15% to 30% of the energy currently used in the baking process. The payback period for such an investment is typically 18-27 months. The potential energy savings in Glasgow could total up to £300.000 in energy costs per year, an equivalent of 700 tonners of CO2 per year. One of the bottlenecks is the initial investments costs, which can be resolved via an Energy Service Company (ESCO).

-

Aquaponics is a very promising technology in which the growing of fish is combined with the growing of biomass, leading to substantial savings in water use (90%) in comparison to traditional farming. The pilot project would include a small scale system (15m2) managed by a local restaurant. The restaurant would benefit from the production of locally grown and sustainable fisch (+/- 250 kg), vegetables (+/- 600 kg) and herbs (+/- 150 kg) per year.

-

Bread to beer is an innovative technology which utilises bread waste in the beer brewing process. Over 200.000 slices of bread are wasted every day in Glasgow, and at the same time hundreds of tons of barley is being used for brewing beer. By using this bread to beer technology, over one third of the resources utilised in the brewing process can be saved while also reducing food waste, by using the wasted bread in the beer brewing process. A pilot would require 500 kg (13.000 slices) of unsold bread to be used in the production of 4.000 litres of beer. When piloted successfully, this technology has potential to use 70 million slice of wasted bread, produce 20 million litres of beer and save over 200 tones of biomass annually in Glasgow.

-

High value cascading. Residual streams from beer brewing (spent grain) can be used to replace up to 50% of the flour needed to produce bread in the baking industry. Over 4.000 tonnes of residual spent grain is produced every year in Glasgow and can be used to make over 12.000.000 loaves of bread, reducing the amount of food waste throughout the city, thus lowering the city's waste treatment costs and resource needs. Additionally, the spent grain can be used in a plethora of other ways including the production of flapjacks, beer snacks, or to grow mushrooms on. After the mushrooms are grown, the mushroom grounds can be deposited into a composter, aiding in the realisation of a circular process.

Links to relevant references:

Circular Glasgow: A Vision and Action Plan for the City of Glasgow